A record 10 staffers from Strip-Till Farmer and sister publication Farm Equipment took to the road this winter to interview manufacturers and find the latest, cutting-edge products.

Held in Louisville, Ky., the National Farm Machinery Show showcased planting, fertilizer, precision technology, harvesting equipment and more.

Below are some highlights from the show’s 880-plus exhibitors.

Planting Equipment

The new Early Riser 2000 Series planters from Case IH is the first to factory-integrate seed placement technologies from Precision Planting into a completely new system. Designed for modern seed types, treatments, populations and conditions, the new planter can be easily customized to a range of soil types, terrain, fertilizer/chemical application needs and varying crop residue management practices. Plus, a streamlined design and tool-free crop changes and adjustments result in simpler maintenance.

Kinze Mfg. introduced its new hydraulic drive option for the 4900 series planter. The hydraulic drive enables farmers to change seed populations while in motion from the cab, making it ideal for variable-rate seeding. The new option will be released with pricing in May 2016 and available for spring planting in 2017. For 2016 spring planting, Kinze is offering a dealer-installed hydraulic drive kit for 16- and 24-row 4900 planters. The 4900 is still available in a variety of drive options, including electric and ground contact.

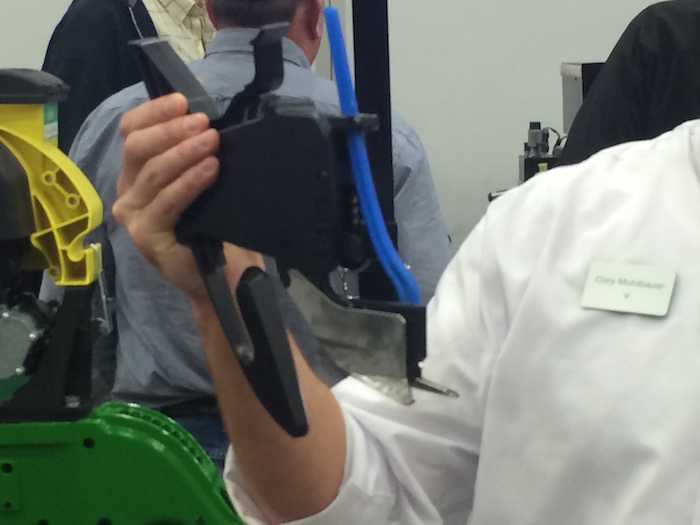

Monosem released its Response Smart Planting System, touted as the first-of-its-kind electronically controlled, adjusted row unit. Each row unit has individual electric downforce control with active on-the-go adjustment, electric variable-rate, seed-metering control and electronic seed-depth control. The new system response utilizes the latest in 12-volt motor and controller technology to provide precise control with high-torque outlet and low power requirements. No hydraulic power is required to operate the system, which reduces the demands on the tractor. The unit is wirelessly controlled by an app from an Android tablet.

Schaffert Mfg. has increased the amount of up-and-down travel on planter row units from roughly 4 inches to 7 inches with its 4 Link Closer system. For farmers planting over terraces, ditches or uneven terrain, the system allows the swing arm closing system to move more independently of the parallel linkage system, thus maintaining improved depth control and seed placement. Schaffert has designed the system for John Deere, Kinze, Case IH, Great Plains and White planters.

Fertilizer Equipment

“AccuShot was developed to give every seed its best shot,” says Mike Cleveland of Great Plains Mfg. The new planter attachment is capable of delivering the correct dose of liquid seed treatment in the furrow during the planting operation. The new seed delivery system is manufactured in partnership with Capstan Ag Systems Inc., which developed the application technology to go along with Great Plains’ seed metering and placement technology. The unit is GPS-driven to maintain a consistent speed and ensure consistent seed placement and starter fertilizer dosage.

According to Tom Evans of Great Plains, the new planting system maximizes early corn development because starter fertilizer is injected at a close — yet safe — distance from each seed at planting. This means 100% of the fertilizer is immediately available to the growing feeder roots. The new system is designed to work with both single and twin-row planters.

Loftness Mfg. expanded its product line in 2016 with new fertilizer application equipment, including the FS800 8 ton spreader. The FS800 features a dual axle and can come equipped with or without brakes. Featured here with a mechanically, chain driven hopper with PTO-driven spinners, it is also available with a hydraulic option. Loftness spreaders will also be available in high-clearance models in March 2016.

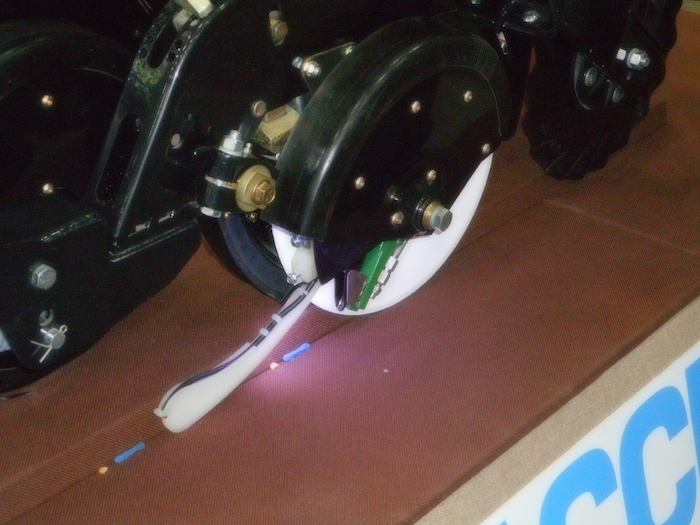

Precision Planting launched its new FurrowJet fertilizer application attachment for planters. The system quick attaches to the planter row unit and delivers fertilizer in three zones — on two wings spaced ¾ inch apart that slice through the furrow sidewall, and also on the seedling. This application method targets the seed roots and crown roots to increase uptake in early plants and create a safe environment to avoid seed burn.

Yetter Mfg. Inc. unveiled its new 2968 row-unit mount in-between dual fertilizer openers. The new fertilizer openers will be available in Spring 2016 and are able to achieve consistent off-the-row starter or nitrogen fertilizer placement. The row-unit mount can be set to apply fertilizer from 1.5-2 inches off each side of the seed. “With the new openers, the depth is adjustable in quarter inch increments and the two wheels are staggered 1.5 inches,” says Derek Allensworth.

Spraying Equipment

Ace Pumps’ new Gemini Dual Pump Kit was developed to allow for the simultaneous application of two liquids at different rates or materials that can’t be mixed during planting or spraying operations. According to Andy Randle, the kit uses one hydraulic supply to run two Ace pumps independently, which allows operators to easily dial in separate application rates.

New in 2016 from CDS-John Blue Co. is the Next Generation Self-Priming Centrifugal Pump with patent-pending 2-in-1 inlet design, providing the flexibility to select from two inlet locations on one pump — the standard lower inlet with backflow flap valve, or higher inlet, allowing outlet lines to drain after shutoff while retaining self-priming capabilities.

GVM’s Erin Hutchison says the new Mako 440/450 sprayer offers a clearance option for anyone regularly running hills. It’s also been designed to be easy enough for first-time applicators, but effective enough for seasoned users. With a stainless steel boom line and either 36 or 46 inches of clearance, the Mako is equipped with a 400-gallon tank and is targeting a spring production date.

Unverferth’s Top Air ATV sprayer delivers an option to get in where the big sprayers can’t. With self-leveling 45- or 60-foot manual front-fold booms and a 200-gallon capacity tank, the sprayer can be pulled behind any 600cc min ATV. The boom features tool-free height adjustment from 12-30 inches with a standard winch.

Strip-Till Equipment

Building off its Pluribus row units, Dawn Equipment Co. unveiled its first complete strip-till unit, the PL 40, with a mounted fertilizer tank and metering system. The system is available in 12, (PL 30) 16 (PL40) and 24 (PL60) row-unit designs, featuring a 3-coulter design that creates an 8-inch wide and 5-inch deep soil profile. The row units only require 10-15 horsepower per row and are designed to be pulled at 8-10 mph through the field.

Harvest Equipment

Along with two new corn heads, Geringhoff also introduced a new flex draper for soybean growers. The new TruFlex Razor is the first “flex-flex” draper that combines a 3-section, flexible frame and segmented reel with a flexible cutter bar. In development for the last 5 years, a Geringhoff spokesman says it delivers the closest, most uniform on-the-ground cutting in the industry, even on hilly terrain. Its center knife drive, center belt drive and integrated airflow system minimize losses and improve performance during harvest.

Seeking to make its Outback Max display a complete “combine friendly” terminal, AgJunction paired with Loup Electronics to introduce its ISO Yield system. Available in Summer 2016, the system allows for multiple layer yield mapping, real-time yield tracking and auto-calibration with yield data saved in .XML format. “Once a user has a Loup yield monitor, it can be paired with any Max terminal that is unlocked for ISO technology,” says Scott Spare.

Precision Technology

Case IH introduced its AFS RTK+, which is the first proprietary cellular RTK network from an OEM. Available for purchase through participating Case IH dealers, the subscription allows farmers to achieve sub-inch, repeatable accuracy through a network of dealer-supported base stations throughout the U.S. and Canada.

Topcon Precision Agriculture introduced the latest addition to its Apollo ECU (electronic control units) line of application rate controllers for sprayers. The new controller supports its Horizon software that runs on X30 and X25 consoles. The controller includes multi-line support for up to 4 lines with automatic switching.

Tracks

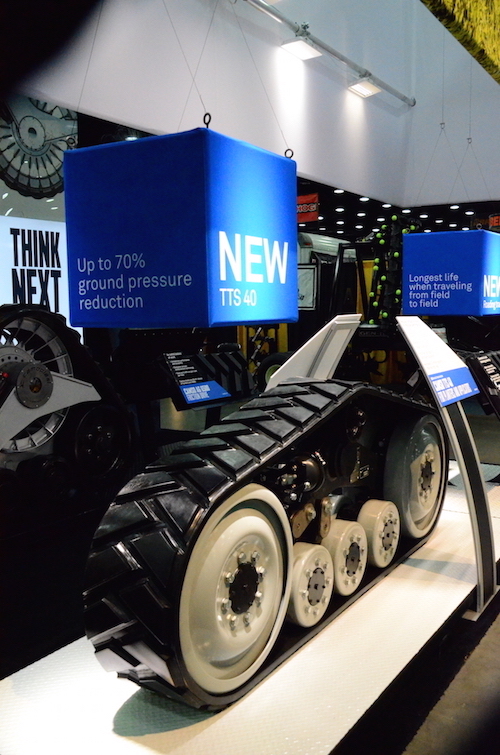

Camso introduced its TTS 40 Series, a narrow-track system for high-capacity, row-crop applications. Available in either a 15-inch width for 20- to 22-inch rows or an 18-inch width for 30-inch rows, the TTS 40 can help farmers save 30-40% on their cost per hour, says Martin Lunkenbein. The tracks have half the contact points compared to dual tire configurations and offer up to 70% ground pressure reduction, fewer pinch rows and less soil compaction. “We’re always thinking about the next generation of products needed and make sure there’s a solid track for that product,” Lunkenbein says.

Tractors

Fendt unveiled its 1000 Vario Tractors series in a private VIP event before displaying publicly the following day. The series puts Fendt into a new power segment in wheeled row-crop tractors (380, 420, 460 and 500 horsepower). The Fendt iD high-torque, low-engine-speed concept combines a new 12.4L 6-cylinder engine with the next generation Fendt Vario transmission. With a comprehensive approach to an entirely new drivetrain, the VarioDrive allows intelligent four-wheel management and the ability to drive both axles independently, says Josh Keeney.