Last updated January 25, 2024

A strip-tiller’s fertilization strategy is influenced by a combination of factors — when they build strips, soil variances and health, climate and equipment setup.

Building a bankable nutrient management strategy has been a common theme throughout the history of the National Strip-Tillage Conference with strip-tillers, agronomists and researchers offering proven methods for creating a balanced, efficient fertility program.

For Shell Rock, Iowa, strip-tiller Jeff Reints and his son, Clay, they’ve long subscribed to the philosophy that fertilizer needs to be placed where plants need it most — in the root zone.

“Why put fertilizer next to the crop?” Jeff says. “Whether you’re strip-tilling in the fall or spring, apply fertilizer where it’s going to provide the biggest benefit.”

Since adopting strip-till more than a decade ago on their 2,000-acre corn and soybean operation, the Reints have made numerous modifications to their system, including a switch from fall to spring strip-till in 2008 to improve crop flexibility and allow more time for residue to break down during winter.

In 2014, they moved from a 16-row to a 24-row Harvest International UltraMax 60 series 60-foot toolbar with Dawn Pluribus coulter-style row units with Montag’s high output dry fertilizer delivery system.

“We upgraded from our 40-foot toolbar this year to cover more acres because we typically like to strip-till 24 hours ahead of the planter, seal in that moisture and have excellent seed-to-soil contact,” Jeff says. “With a 60-foot rig, we can run about 8¼ mph, which allows us to cover about 60 acres per hour, well a head of the 5½ mph we run our 24-row Case IH planter.”

The Zoning Effect

One constant for the Reints has been their commitment to banding fertilizer in the strip because it saves time, fuel and fertilizer costs.

For nearly a decade, they’ve yielded 10% above their county average for corn, and Jeff says their crop insurance agent tells them they have one of the highest actual production history (APH) numbers on farm ground that is several points below the county average. (CSR-corn suitability rating)

At the first National Strip-Tillage Conference in Cedar Rapids, Iowa, the Reints shared 2014 research, comparing broadcast application of fertilizer in a conventionally tilled cornfield with banded application in strip-tilled field.

To illustrate their comparison, — see video below — they pulled corn plants from the two different fields and mounted 8 plants on a board, 6 inches apart, to represent a 34,500 planting population. The Reints then weighed, on a gram scale, the exact amount of potassium (K), phosphorus (P) and sulfur applied for a 200-bushel-per-acre yield goal.

For the broadcast application, they applied 160 pounds per acre of diammonium phosphate (18-46-0), 100 pounds per acre of potassium chloride (0-0-60) and 100 pounds per acre of ammonium sulfate (21-0-0-24). The total application (360 pounds) costs $74 per acre.

“We measured it out to 3.75 grams of fertilizer per square foot, which meant that this is what we’d see on the soil with a broadcast application by a floater,” Jeff says.

For strip-till, the Reints reduced application rates by 25%, banding the fertilizer in an 8-inch wide by 5-inch deep strip. They applied 120 pounds of diammonium phosphate, 75 pounds of potassium chloride and 75 pounds of ammonium sulfate.

Not only was banding a cheaper method — $18 less per acre than broadcast application — the concentration of fertilizer was higher with 10.5 grams per square foot. Overall, the Reints estimate a fertilizer application savings of more than $20,000 per year with banded application in strip-till, vs. broadcast application in conventional tillage practices.

“We know we can reduce application rates with strip-till and talking with agronomist Brian Hefty, he told me that broadcast rates have to be 50% higher than banded application to achieve the same effect on crops,” Jeff says. “In our example, what the root mass is seeing with strip-till is the equivalent of broadcasting 1,010 pounds per acre of fertilizer.

“If you call up your local co-op and order 1,010 pounds per acre, you will be getting a Christmas card from them because that would be one giant order.”

Strip-till is also saving the Reints more than $4,000 per year in fuel costs because they only make one pass in spring to place fertilizer, rather than multiple field preparation trips in a conventional tillage system.

“When our combine leaves the field, we are 0.40 of a gallon of diesel from planting the next crop,” Jeff says. “We only burn about 0.40 of a gallon per acre applying one-third of our nitrogen, all of our potassium and phosphorus and building the strip, all in one pass.”

Born to Run

Greeley, Colo., soil scientist and independent consultant Mike Petersen says the science behind fertility placement has improved tremendously over the years, and that broadcast fertilizer should be a thing of the past.

"We should put the fertilizer in the ground where the plant's going to find it," Petersen says. "The plant doesn't have eyes, hands or a nose. It has to run to the fertilizer. If you put fertility right in front of the plant, it will find it, and you'll succeed and profit from it.

"Did you know corn has two different root systems involved in its early growth? Fertilizer placement makes a difference in the first 45 days of growth. For example, if you’re using boron, you need to apply it during the first 45 days of life. Manganese needs to be applied in the first 15 days. If you don’t apply it in the first 15 days, you’re out of luck. Knowing what goes on in those first 45 days is really important. It makes a difference in how we feed the plant and using a strip-till system helps make it happen."

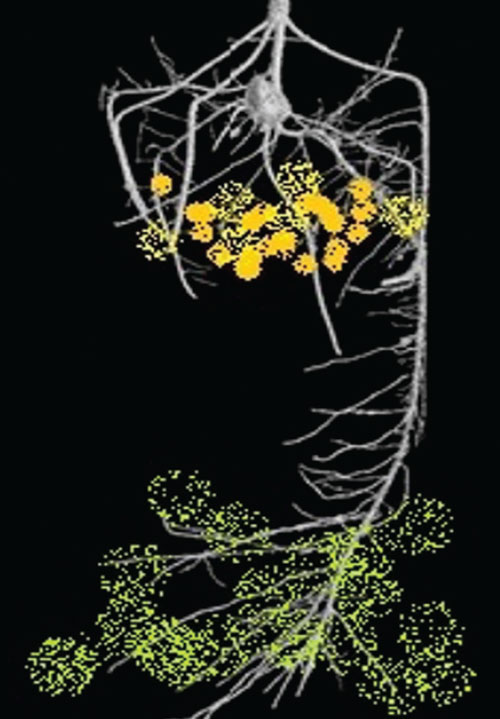

Placing nutrients as shown in the above picture enables the root to run into the products, Petersen says. The green dots represent nutrients applied with strip-till 6-10 inches deep, where the roots grow 25-40 days after emergence. The yellow dots represent nutrients applied with the planter.

Banding with Care

One of Persia, Iowa, farmer Bill Darrington’s guiding principles for managing his operation is to treat it like a human being. The longtime no-tiller and strip-tiller builds his fertilization strategies around the philosophy that like humans, crops need to eat on a regular basis to grow and remain healthy.

“It takes multiple feedings for us to maintain complete nutrition and stay energized,” Darrington says. “It’s the same concept with plants. We know that corn plants determine how many rows will be around an ear at V3 stage, and how long that ear will be at V8.

“It’s all about basic pre-natal care to promote a healthy and happy growing environment to maximize yield potential.”

But he adds that continuously feeding crops fertilizers with potentially harmful elements, or the equivalent of human “junk food,” can stunt plant growth and sterilize soils. The long-term practices of banding fertilizer beneath the soil surface, the use of organic-based nutrients, and multiple, timed applications throughout the growing season have contributed to strip-tilled corn yields over 290 bushels per acre on some of Darrington’s highly variable soils and sidehills.

While he typically doesn’t apply any fertilizer at planting, Darrington has developed a comprehensive fertility program to suit his operation, with an eye on environmental stewardship, organic efficiency and balanced soil health This starts with a broadcast application of 150-200 pounds per acre of ammonium sulfate (AMS) in early winter to alter the carbon-nitrogen ratio in the residue and jump-start decomposition.

The cornerstone of his split-application system is the banded placement of nutrients in spring with the strip-till rig. With the front anhydrous knife on his 18-row Blu-Jet dual-placement strip-till toolbar, Darrington injects 40 gallons per acre of 28% N and 5 gallons of ammonium thiosulfate, P and K (7-25-5), plus, zinc and sugars in the strip, about 7 inches deep.

Then a second application system of the dual-tube knife applies about 10 gallons per acre of a 2-16-14 blend from Indiana-based CarboTech America, a direct liquid fertilizer supplier.

“We drilled a small hole in the back of the second tube to shoot the product out behind the knife. This is 2 inches shallower than the 28% and keeps the tube from plugging, and gives us a staggered application site in the strip,” Darrington says. “We don’t want to apply everything all in one spot and walk away. I want that soil profile to be layered with nutrition, eliminating our corn from being pale yellow until it finally runs into the fertilizer hot spot.

“The secret to my success is placing a little at a time and allowing the root system to run into more nutrition as it grows.”

Darrington says the dual application is contributing to more consistent emergence and corn plant health throughout the growing season. But just as important as the timing of applications, is the type of fertilizer being banded in the strips.

He recalls a 1999 visit from mentor Ray Rawson, who helped change Darrington’s thinking about how non-organic elements in fertilizers can negatively impact soil health.

“Ray came to my farm and in 30 seconds could tell I was still applying anhydrous ammonia because he showed me a hardpan and crack in the soil where the anhydrous knife ran,” Darrington says. “That was the last year we ran anhydrous. Today, I have a much better understanding when banding fertilizer, it is always important to remember the good and the bad ingredients are all being banded in the root zone. This could be salt or chloride or even some heavy metals.

“The million dollar question for me is always, ‘What else is in it?’ because I’m willing to pay a little more for products that are going to promote and preserve soil biological health.

Form, Rate, Timing and Depth

As one of the leading researchers on fertility placement, Purdue University agronomy professor and 2014 National Strip-Tillage Conference speaker, Tony Vyn, understands as well as anyone the comparative benefits of banded fertilizer applications in different tillage systems.

Banding nutrients may enable strip-tillers to gain application efficiencies, he says, but growers shouldn’t make decisions in a vacuum.

“Don’t assume that you will have an overall reduction in long-term phosphorus and potash requirements in strip-till,” Vyn says. “You will probably be able to apply less phosphorus and potash with strip-till than by broadcasting it. But you still have to meet the nutrient requirements for crops, and phosphorus and potassium removed by the grain needs to be replaced.”

Banding N and P provides flexibility, as strip-tillers are less dependent on applying starter with the corn planter, Vyn adds.

“For maximum starter benefit with strip-till, phosphorus banding should not exceed 3-5 inches deep in the fall,” he says. “For nitrogen, it depends on the form, rate and timing. Strip-tillers should only apply anhydrous ammonia in the fall, when the depth really doesn’t matter.”

Strip-tillers using anhydrous ammonia in the spring should place it at least 7 inches deep, Vyn says. However, there are two exceptions to this rule.

The first is the anhydrous is placed at least 3 inches away, in an offset manner, before the radical roots reach the anhydrous zone. The second is that there are at least 2 weeks or 1-2 inches of rain between the application of anhydrous and planting corn.

Vyn stresses that these recommendations depend on which form of N — anhydrous, UAN or urea — strip-tillers select, as well as the depth of placement.

“In the spring, all of these forms of nitrogen could be pre-plant applied in the intended corn-row areas — even as shallow as 5 inches deep — if less than 75 pounds of actual nitrogen is applied per acre,” he says. “However, at 100 pounds of actual nitrogen per acre applied in the spring, pre-plant and in the row zone, the deeper the fertilizer is placed, the better.”

Strip-tilling corn in the spring involves trade-offs. In a much wetter environment, strip-tillers may be losing some opportunity for enhanced root growth in corn due to smearing and clodding, Vyn says.

For this reason, he is very nervous about spring strip-till for corn, with in-row placement of high rates of N — especially anhydrous and urea.

“If a strip-tiller is applying 100-200 pounds of UAN on 30-inch spacing, it should be placed 5 inches to the side of where the corn will be planted,” Vyn says. “Placing this rate of UAN 5 inches below where the corn is planted might be OK.”

For many strip-tillers, the system’s attraction includes putting fertilizer where it can be easily accessed by the crop’s roots. But applying fertilizer in a band may be too concentrated, Vyn says.

“There are some benefits of mixing fertilizer in the soil,” he says. “But in my experience, continued deep-banding phosphorus and potassium using RTK in the same root zone — applying a 2-year, crop-removal rate before corn — is not as effective, yield-wise, for a multiyear strip-till corn and no-till soybean sequence as broadcasting the fertilizer is.”

Strip-tilling and deep-banding of P and potash is ideal from an environmental perspective, Vyn says.

One option is to deep-band all of the P, but broadcast at least some of the potash. The other option, especially for potash, is to move the deep-band position regularly to try to achieve a more uniform soil distribution of K.

“For example, move phosphorus and potash 10-15 inches to the side of where the corn was planted last, if you’re only deep-banding,” Vyn says. “This is especially true for phosphorus. You need to move the zone, or it will be less efficient.”

The Funnel Effect

Another benefit of banding fertilizer is that it’s more accessible to moisture, Reints says.

“The most important thing you need to get fertilizer going is moisture,” he says. “When I was in the field this spring, the light bulb went on in my head that corn plants are great funnels of moisture to the root mass.”

One experiment the Reints plan to conduct in the future is to measure how much water falls between the corn row compared to the amounts that filter down to the roots.

Jeff says he may put a corn plant in a coffee can to try and record the amount that is captured in the can, using a sprayer to apply water.

“Our best estimate is that about two-thirds of moisture reaches the root mass and only about one third lands in between the rows,” Jeff says. “I’d like to get a more accurate measurement, but it makes sense to place our fertilizer where the most moisture is going to reach it.”

Related Content

- Banding vs. Broadcast: Comparing Strip-Till Fertilizer Application Strategies: Iowa strip-tillers Jeff Reints and his son Clay share their trial and error approach to comparing the benefits of banding fertilizer vs. broadcast application.

- Fertilizer: Comparing Broadcast to Banded Application: Jeff Reints, strip-tiller from Shell Rock, Iowa, explains the fertilization experiment he conducted comparing the results of broadcast application on 30-inch row corn, planted at 34,000 population, vs. a banded application of nutrients below the soil surface.

- The Do’s and Don’ts of Fertilizer Banding: Purdue University agronomy professor Tony Vyn shares results of recent fertilizer application research and discusses considerations and cautions for developing a practical nutrient management plan in strip-till.

- Hitting the Sweet Spot with Strip-Till Fertilization Practices: Practical, experience-based advice on the right timing, depth and rate to apply fertilizer and authoritative results all contained in one free, reader-friendly eGuide.

- Dig Deep to Uncover Root of Strip-Till Fertility: Holding plants accountable for their yield promise requires an understanding of how fertilizer timing, placement and performance intersect with root structure and development, according to veteran agronomist Mike Petersen.

- Should You Quit Using Anhydrous Ammonia?: Bill Darrington knows his comments aren’t exactly popular, but he has no problem telling growers they need to give up anhydrous ammonia — especially if they care about soil health.