33-year-old Alex Harrell, who grows corn, soybeans, wheat and watermelons across 3,000 acres in Smithville, Ga., learned a lot from one of his biggest mentors — Randy Dowdy — when Dowdy shattered the soybean yield record with 190.23 bushels per acre on his Valdosta, Ga., farm in 2019.

“Randy Dowdy truly set the bar and gave me something to chase,” Harrell says. “He made me realize that it was possible to achieve record yields here in Georgia.”

Motivated by his mentor’s success, Harrell focused on building what he calls the perfect plan for high-yielding soybeans, with assistance from his crop consultant and fellow Georgia strip-tiller, Caleb Traugh, who stresses the importance of a complete fertility package.

“When I first started strip-tilling, I was only applying 1-2 different products with our strip-till pass,” Traugh says. “But we really took things to the next level when we built this complete fertility package — containing not just nitrogen (N), phosphorous (P) and potassium (K), but also micronutrients to make sure the crop has what it needs to reach its full potential.”

My High-Yielding Soybeans

Hybrid: Asgrow AG48X9

Seed Treatment: Brandt SeedZone Zn

Plant Population: 85,000/acre

Harvest Population: 77,000/acre

Crop Protection: XtendiMax, Roundup, Valor, Revytek

Fertilizer: N, P, K, Brandt Smart Trio, Brandt Smart B-Mo, Brandt Smart Quatro Plus, Brandt Smart K B, Brandt Southeast Crop Mix

Planter: Custom with John Deere frame & Precision Planting attachments

Combine: John Deere S770

Equipment Dealers: Lasseter Equipment Group (Moultrie, Ga.), Flint Equipment (Americus, Ga.)

Soil Type: Sandy Loam

“We use all the micronutrients — zinc, manganese, magnesium, molybdenum, boron, copper and iron,” Harrell says. “It’s like baking a cake. If it takes 15 ingredients to bake a cake, you can probably leave 2 of them out and still have a cake at the end of it. But it won’t be as good as if you used all the ingredients. It’s the same thing with a crop.”

Planting After Dark

Harrell put the “perfect plan” to the test on a 10-acre block within a 60-acre sandy loam field equipped with pivot irrigation. The process began in late summer 2022 when he pulled 1-acre grid samples across the entire field after corn harvest. Harrell applied lime at variable rates based on the results. He then drilled in a 4-way winter cover crop mix of cereal rye, daikon radish, oats and triticale at a rate of 35 pounds per acre in the fall.

“The combination of cover crops and strip-till has been a game changer for us,” says Harrell, who farms with his dad, Rodney. “Not only do cover crops improve water infiltration and reduce the amount of water we need to irrigate soybeans, but they also help with weed suppression and, most of all, erosion control over the winter months.”

Harrell terminated the cover crops with Roundup and Valor in early March. He then applied chicken litter and gypsum to help build calcium base saturations. In early April, 3 weeks after terminating the cover crops, Harrell used a 16-row Schlagel Rapid Till strip-till machine, which has 3 coulters, a shank and a rolling basket, to make strips 10 inches deep into the terminated cover crop ground.

“Cover crops and strip-till have been a game changer for us…”

A couple days later, it was time to plant into the strips. Rain was in the forecast. Harrell wanted to stay ahead of it, so he jumped in his custom-built planter and started planting the 60-acre field at 10 p.m.

“We won’t hesitate to plant in the middle of the night if we’re racing a rain,” Harrell says. “Our planter is completely custom built, with a John Deere frame and Precision Planting parts. It has DeltaForce — an automated row-by-row downforce control system. We change 3 times per second as we’re going across the field. It has vDrive electric drive meters, and FurrowForce, which is a two-stage closing system that helps a lot with emergence.”

Harrell planted an indeterminate soybean variety from Asgrow, AG48X9, coated in their standard practice seed treatment with the addition of Brandt SeedZone Zn, in 30-inch rows at a rate of 85,000.

“We apply multiple biologicals and plant growth regulators (PGRs) in-furrow and post-emerge,” Harrell says. “We also run a 3-by-3-by-3 fertility system at planting, applying N, P, K and micronutrients 3 inches from each side of the row and 3 inches deep through Precision Planting’s vApplyHD. I place fertilizer 3 inches deep so it’s below the seed, because roots grow down. Then I go 3 inches to the side because I apply a fair amount of N, and I don’t want it to be too close to the seed. It gives me a buffer zone.

“It’s a systems approach. There’s no silver bullet, just a lot of good products applied at the right time, and a lot of good weather. One rain event at the wrong time could’ve ruined everything.”

Weathering the Storm

A packing rain hit Harrell’s farm shortly after planting, resulting in a final stand of 77,000. Mother Nature threw another curveball with a 10-day flooding rain in early June.

“The packing rain hurt our stand initially, and the 15-inch rainfall over 10 days in June didn’t help matters either,” Harrell says. “Fortunately, right after the rain, it was hot and sunny, and everything dried up. We have spraying drones, so we were able to keep spraying foliar fertilizers throughout those rain events to keep the crop pumped up and growing.”

GIANT BEANS. Alex Harrell knew he had a special soybean crop but didn’t realize its record-breaking potential until measuring pod load and bean size. He says late-season management was key to maximizing yields. Images: Alex Harrell

Harrell used a total of 5 different Brandt foliar fertilizers — Smart Trio, Smart Quatro Plus, Smart B-Mo, Smart K B and Southeast Crop Mix. Even during the heavy rainfall events, he never deviated from his plan, making only a few alterations when weekly tissue samples revealed specific nutrient demands.

“We pull tissue samples every Monday, starting at V1 all the way up to desiccation,” Harrell says. “We base our fertility applications on the trend line from the samples. We can see if anything is rapidly declining or increasing, and we make our prescriptions based on that.”

Throughout the growing season, the crop didn’t go more than 7 days without a fertilizer or fungicide application.

“The soybean plant takes up about 67% of its fertility after R1,” Harrell says. “That’s when we start hammering it with PGRs, foliar fertility and fungicides. We band nutrients next to the rows with Y-drops and inject nutrients through the pivot irrigation system.”

Harrell made a total of 6 fungicide applications — 1 in-furrow at planting, followed by 2 in the vegetative stage and 3 more in the reproductive stage with Revytek from BASF.

Chase for 200

As the season progressed with ideal weather, it became clear something extraordinary was growing. Harrell predicted a yield of around 150 bushels per acre as harvest approached.

“I knew they were good soybeans, but I didn’t think they were much better than 150 bushels, mainly because I’ve personally never seen anything better than that,” Harrell says.

He truly began to understand the record-breaking potential of the crop after he desiccated it with herbicide and saw pod load and bean size.

“We desiccate the soybeans because they’re indeterminate, and they’ll keep growing in our heat in the south,” Harrell says. “We desiccate when we get complete bean separation from inside of the pod. We do it to get the soybeans to dry down for harvest. If not, they’ll still have green leaves and stems that will rot in the high humidity.”

“The soybean plant takes up about 67% of its fertility after R1…”

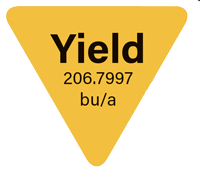

The “perfect plan” came to fruition in late August with a world record-breaking yield of 206.7997 bushels per acre — more than quadruple the average soybean yield of 45 bushels per acre in Georgia. After celebrating the record with his dad, Harrell wanted to personally break the news to his mentor, Randy Dowdy.

“Unfortunately, Randy was undergoing open heart surgery at the time, so I wasn’t able to talk to him,” Harrell says. “But his wife called to congratulate me and let me know Randy was doing well in recovery.”

Harrell credits much of his success to Dowdy’s pay-it-forward approach to farming. Judging from Harrell’s willingness to pick up the phone and share his playbook, it won’t be long until Harrell has a strip-till mentee of his own, if he doesn’t already.

“My biggest takeaway from the 2023 growing season is to never give up,” Harrell says. “We didn’t have the best stand, but we never deviated from our plan. We carried it all the way to the end. I learned that late-season management is critical for high yields. When most people start giving up on soybeans is when we start really cranking up our management.”