Ag Tire Talk is a blog where James Tuschner asks tire manufacturers and other industry experts for their opinions and advice on key topics in the world of ag tires. This edition asks tire manufacturers about key differences and important takeaways regarding ag tire tracks.

AG TRACK TALK KEY TAKEAWAYS

SOUCY: “In the agricultural world there are basically two types of tracks: Friction Drive and Positive Drive.”

ZUIDERG: “The most important difference between the two types of tracks is the method of submitting power from the machine to the track and visa versa.”

TRACKMAN: “The Friction Drive system is driven solely by friction, which gives it a less complicated and cost-effective design.”

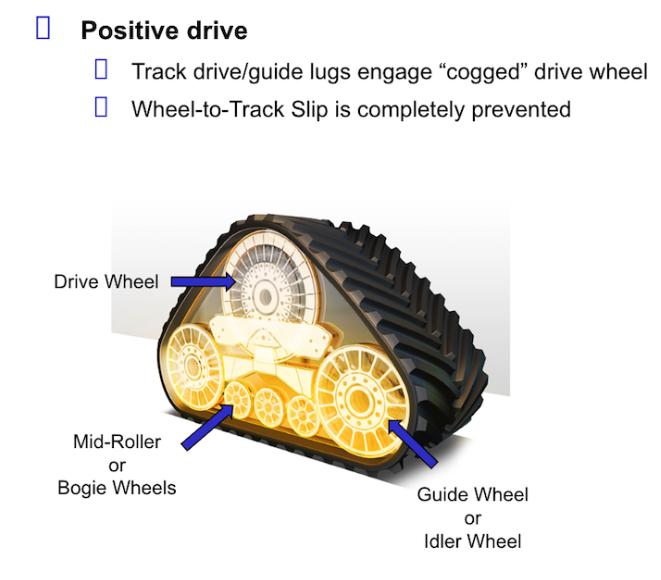

CAMSO: “Positive Drive is different…as there is less tension on the belt, and it is technically pushed by the sprocket, whereas drive lugs on the underside of the track fit perfectly with the sprocket.”

Camso

David Graden: Operational Market Manager – Agriculture

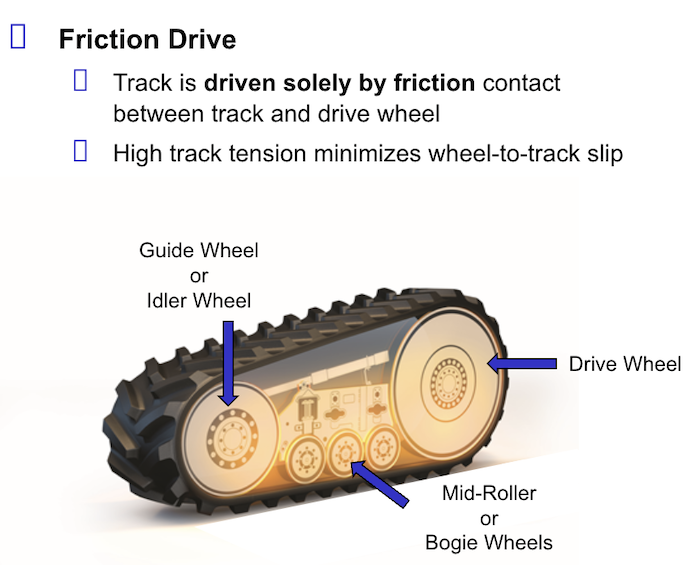

Friction & Positive Drive Agricultural Track Systems are similar in that they both contain a drive wheel, guide wheel (also known as Idler Wheel) and mid-rollers (also known as Bogie Wheels). However, the configuration of these parts and the design of the track makes them very different.

The Friction Drive system is as it sounds. Typically, these are seen in pairs (as opposed to 4 tracks) on a machine. The tracks are elongated and put under tension and, of course, driven by friction. Additionally, the track curves 180 degrees around two wheels; the drive wheel at the rear and the idler wheel at the front.

The Positive Drive system is different in that it is triangular shaped with two idler wheels at the bottom corners and a drive wheel, or sprocket, at the top. There is less tension on the belt, and it is technically pushed by the sprocket, whereas drive lugs on the underside of the track fit perfectly with the sprocket.

As it relates to which drive system is better or worse, I don’t have an answer for this. It all boils down to manufacturer choice and/or the machine limitations and application these machines are designed for. From a producer’s perspective, you will purchase the machine that best fits your farming needs or the necessary performance needs. For Fendt, AGCO and Caterpillar, they only use Friction Drive systems. Case IH, Versatile and New Holland are only Positive Drive. Then, John Deere and Claas are a combination of both drive types. John Deere continues to build an 8RT (2-track Friction Drive) and an 8RX (4-track Positive Drive). They do this to meet the specific needs of their vast customer base.

In fact, Michelin has developed and invested heavily in both friction drive and positive drive technology, as we still see a very strong future and growth for both. Within the last year, we have invested an additional $100M to expand our manufacturing capacity to meet the rapidly growing demand for each.

Finally, we continue to partner with all major OE manufacturers when developing undercarriages (systems) and track belts. This ensures we are on the right track to meet all the needs of our customers.

Trackman by Loc

Dan Fullenkamp: Business Development Director

Friction Drive and Positive Drive systems both require Rubber tracks that are held in place with tension. Both have wheel paths where bogie (mid roller) wheels ride and distribute the weight of the vehicle with lower ground pressure; tracked systems transfer power with more efficiency (less slip) than tire options on the same equipment (vehicle).

Both Friction and Positive drive systems utilize track construction which is based on a main cable that is helically wound to ensure track strength. The size of cable varies from manufacturer to manufacturer. Cable strength and the number of cable wraps providing the overall strength is more meaningful than the diameter of a given strand of cable. In addition to the cable, the track carcass is reinforced with multiple wire bias plies for increased lateral strength and alignment features. The number of plies of wire reinforcement can vary depending on the vehicle and the application.

The Friction Drive and Positive Drive tracks have unique structural and functional differences that separate their strengths and weaknesses from each other.

Friction Drive Benefits

The Friction Drive system is driven solely by friction, which gives it a less complicated and cost-effective design. Friction tracks incorporate “guide lugs” on the inner or wheel path side of the tracks to help ensure that the track maintains it’s position on the undercarriage system. The size of the guide lug differs from manufacturer to manufacturer. Trackman typically utilizes a greater number of guide lugs for increased efficiency, reduced stress, and longer life on these lugs as they transition around the drive and idler wheels of the friction drive system.

Friction Drive Drawbacks

When friction is lacking, it is in slippery (muddy or frosty), or wet conditions, when the belt could slip. This is one of the most significant drawbacks of the otherwise reliable design of the Friction Drive.

Positive Drive Benefits

The drive wheel of a Positive Drive system engages with the track drive lugs, preventing track slippage from occurring- this can be a better option when working in a wet slippery environment and is often utilized in higher horsepower equipment.

Positive Drive Drawbacks

The engagement precision required with this set up is more costly but more reliable.

In higher torque applications as well as many sidehill applications Trackman’s industry leading innovations of ARMORLUG™ and ARMORLUG ULTRA™ provide users with reinforced drive lugs for greater performance and longer life. In short, the pros and cons for the particular application must be countered by the investment in order to make the best decision between Friction & Positive Drive Track Systems.

With either a Friction or Positive Drive system, always follow the guidance of the manufacturer, with regards to applications, speed, and load.

Soucy Track

Marc Mcdonald: Territory Manager

In the agricultural world there are basically two types of tracks: Friction Drive and Positive Drive.

Friction Drive

Starting with the Friction Drive; these are the most common. A friction drive belt, as implied by its name, is a track that is tensioned to smooth rubber wheels much like a conveyor belt. The tractive force generated for propulsion is the friction between the drive wheels and the roller path of the track.

Most friction drive machines are used for general agriculture whereas positive drive track machines are used where more tractive force is required.

Positive Drive

The positive drive track is primarily a friction drive belt (most of the time) with metal sprockets that are interlaced with rubber blocks. At the point the friction drive is overwhelmed, the sprocket catches the rubber blocks for a positive engagement without any noticeable difference.

COMPARISON

Both Track Types

- Are similar in construction.

- Have an integrally wound main cable (zero cable) continuously from one side to the other, for strength.

- Rubber outer drive lugs for traction.

- Have a smooth roller path for the wheels to transfer weight of the machine to the ground.

- Have differing layers of steel and synthetic fabrics for strength in different applications.

Difference

- Friction Drive tracks have Guide Blocks, Positive Drive tracks have Drive Blocks.

Friction Drive Benefits:

- Fairly simple. Two guide wheels, two drive wheels, a track, and bogie wheels to support.

- Typically have less problems with the undercarriage.

- Last much longer as there isn’t as much adverse contact between the components.

Friction Drive Drawbacks:

- Friction Drive tracks (two tracks) are harder to ballast front to rear with cyclically loaded equipment.

- Friction Drive tracks lose much of its internal traction when moisture levels are too high (mud and/or water) resulting in difficulty maintaining forward direction or steering at times.

Positive Drive Benefits:

- More torque to the ground in difficult or high traction situations.

- Better control maintaining direction and turning in wetter conditions.

Positive Drive Drawbacks:

- Much lower lifespan than friction drive.

- Typically more problems with the undercarriage.

- Drive lugs are the workhorse of this track. Damage to the drive lugs from alignment, material ingestion, or over pulling greatly diminishes life expectancy of the track.

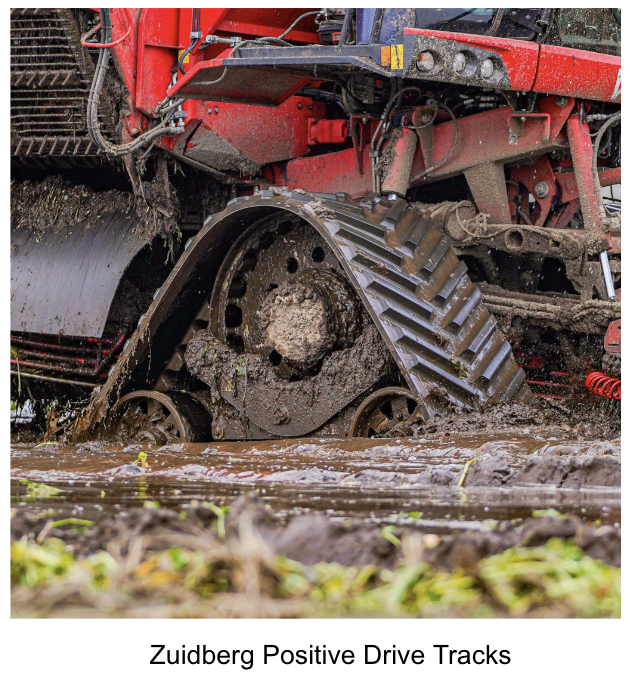

Zuidberg Group of Companies

Reint Bannink: Manager Assembly, Coating & Rubber –

The looks and feel of both mentioned tracks as such show only small differences. Both tracks have lugs on the inside and lugs on the outside. Length and width might differ from one to another, but within the range of positive drive tracks as well as within the range of friction drive tracks there is a wide range of length and width available. Length and width all are related to the system in which they are used and areas with specific demands. The type of outer lugs is related to the type of soil and circumstances of usage, which may differ a lot, regardless of whether it is a positive drive or friction drive range of tracks.

The most important difference between the two types is the method of submitting power from the machine to the track and vice versa. In a positive drive system the power is exchanged by a set of sprockets in a so called sprocket-wheel. The sprockets pull the track ahead like a chain is pulled by the chainwheel. Doing so, a large amount of force is placed on the lugs with high torque on the track. The inner lugs, also called ‘drive lugs’ need to deal with these huge forces and power. The forces applied to the inner lugs are transferred into the carcass of the track. So the enormous amount of energy needs to be adapted in such way that the carcass is remaining stable and delivers the power to the outer lugs and through them into the soil for the required traction. In order to keep the track in place, and to avoid hopping of the track over the sprockets some tension is given to the track with a small hydraulic cylinder in the track frame.

Where the positive drive track is driven by sprockets, the friction drive track is, as named, driven by friction by the wheel on the rear. To apply high friction, an extremely high tension in the track is demanded. This is applied by heavy hydraulic cylinders in the track frame. The tension in such a system is 10 to 15 times higher than in a positive drive system. The lugs on the inside of the track in a friction drive system are for guiding only- they do not have any influence on traction.

At Zuidberg we are able to support both systems, in a wide variety of widths, lengths and type of lugs, meeting market special demands and requirements for most customers.

All information is provided solely to provoke thought. All deductions made from information on this site must be confirmed by Certified Ag Track Dealer before use. Ag Track Talk does not recommend anyone conduct track service work with exception of Certified Ag Track Dealer Professionals.