I’m in charge of sales development at H&R Agri-Power, a Case IH dealership based out of western Kentucky. I’ve been with the company 40 years. I also work with many growers in western Tennessee on highly erodible soils.

Hopkinsville, Ky., is home for me. If you go straight south within our county, you’ll see an historical placard recognizing the Harry Young family. Martin Enterprises is located over in Elkton, Ky. The Eugene Keeton farm is in Todd County, Ky. Phil Needham is also close to us. We’ve been heavily influenced by no-till pioneers. But around 2012, we reached a yield cap with the no-till practices we’d been using for so long, and we knew something had to change.

The farmers in this area are on the leading edge as far as embracing new practices and taking calculated risks. In 2015, a customer told me he was interested in strip-till. “I need a price on a strip-till rig, can you give me one?” he asked. I’m like, “What’s strip-till?”

Good First Impression

The initial results with strip-till were positive in our region. People said it was working, they were getting a 20–30-bushel yield bump, and the practice was legit. Fall strips are the way to go for us because of time constraints. Plus, we have enough freezing and thawing that if we do have some coarse, chunky strips, they seem to melt well. We’ve found that a 6–7-inch shank depth works well into soybean stubble. As we started learning more about strip-till, we looked at incorporating cover crops into the system. We broadcasted cover crop cocktails at high rates in the fall, and then we tried to strip into them in the spring. Everything plugged up, and we couldn’t get them terminated quick enough. It was one of many good learning experiences with strip-till.

We’ve settled on cereal rye at a very low, practical rate. On a neighboring farm, we apply it with a strip-till rig, which I call Frankenstein. It’s 16 feet wide with 3 delivery hoses per row unit. It applies cover crop seed, fertilizer and herbicide in 1 pass.

The Next Steps

About 12 of our customers were strip-tilling from 2015-18. They were collaborating with each other and weren’t in competition. At the time, we stalled out and got complacent. But then in 2020, our passion was reignited at a meeting where growers learned they’d have to get serious with strip-till if they wanted to break our area’s yield caps.

“Farmers who tried strip-till for the first time came back fired up…”

Since then, we’ve become the go-to dealership for strip-till in our region. We have strip-till equipment available on a rental basis to give growers a chance to experiment with it. We also have an agronomist on board to make better decisions about inputs.

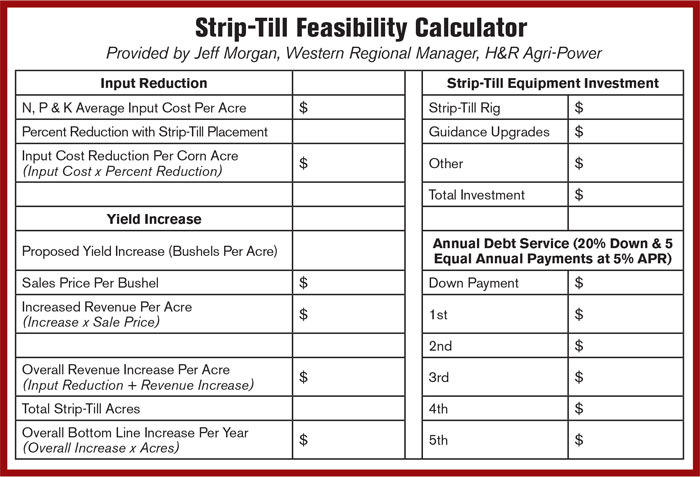

We developed a strip-till feasibility calculator to help curious farmers determine if strip-till can work in their operation. It’s a spreadsheet that serves as a starting point for the economic and management considerations of adopting strip-till. It’s a conversation starter. It’s a way to plug in numbers and shake a few things out. It’s like first base in a baseball game. After going through it, we throw the calculator away, and the conversation gets a lot more in-depth and technical.

CRUNCHING NUMBERS. Jeff Morgan’s feasibility calculator quantifies the potential economic impact of strip-till with interested customers. Photo by: Jeff Morgan

There were no baby steps. Farmers who tried strip-till for the first time came back fired up. Over the past few years, we’ve had people knocking on the door saying they’re all in and want to move to strip-till and deep-placed fertilizer and do it all at once — no going slow. Strip-till improved yields enough for growers to pay for the investment. This will drive sustainability into the future, just as no-till did many years ago.