Prior to working with the UNL TAPS farm management program (Testing Ag Performance Solutions), I had not fully understood the economic impact that the seed selection decision potentially has on farm profitability. Sure, I knew that paying too much for seed relative to its return results in a reduction of profit, and yes, I recognized that a certain degree of productivity is required to cover expenses and have a healthy cash flow, but it was a surprise to me to find out just how large the decision using the right seed at the right price is and that it can significantly alter profitability.

When TAPS competitions started, I assumed that most competitors’ seed choices would not play as a major role in determining the economic winner as they have and that seed selections would likely result in somewhat similar yield outcomes. After examining and analyzing the 2018 TAPS results, it became evident to me that I have underestimated the impact and value of this choice. A solid-performing hybrid at the right price makes a considerable difference in both costs and returns.

In the next few pages, an economic analysis of the 2018 TAPS seed decisions is presented. This comparison is made using the profit relationship, measured by the change in revenue due to the yield difference in hybrids, minus the change in costs due to planting a different hybrid.

A side note is this same method is appropriate, useful, and needed for many of the production decisions. The planting cost difference among the various hybrids is straightforward and easy to determine since seed costs are known at the time of planting and each competing farm’s planting populations are known. The planting cost difference is simply the costs of planting hybrid A1 versus the currently planted hybrid B#. There are 11 B hybrids, identified here as B1 through B11. For practical purposes, seed costs are reported on a per acre basis. It is further recognized that all other costs of planting are constant and don’t change by hybrid, since they are planted using the same equipment, in the same field.

Seed costs are priced by the bag. A bag of corn seed is standardized to contain 80,000 seeds, making it easy to determine cost in terms of cost-per-1,000 seeds. Each hybrid has unique technological components, distribution and development history with many different pricing schemes. Hybrid A1 was selected as the base hybrid for this analysis since it has the largest number of replications and observations which are helpful in creating a statistically viable model used as the basis to determine yield differences among hybrids. This model was used to simulate yields of the base hybrid (A1) based on irrigation quantities; and N fertilizer applied by the various competing farms that planted B# hybrids. These simulated A1 yields were compared to the planted B hybrid yields by farm #. Coincidently, the A1 hybrid turned out to be the best value to plant and is the second most productive corn hybrid for the 2018 TAPS production year.

Cost Differences

In the 2018 UNL TAPS contest, twelve different corn hybrids were planted. This seed originated from various seed suppliers and companies. The actual hybrid names are listed in the 2018 UNL-TAPS banquet report found at the taps.unl.edu using the Report/Data tab. Table 1 in this report lists each competitor by farm number, assigned hybrid identification number (HIN), current seed costs per acre (i.e. farms 1, 12, 13, 17 and 18 were planted with hybrid A1), projected costs of planting the base A1 hybrid, with the designated seeding rate, and the difference in costs per acre. This last value, difference in cost, is either a savings or loss and is derived from the substitution costs of the hybrid A1 seed versus the cost of the planted B# hybrid.

Negative values in the last column of Table 1 indicate that hybrid A1is more expensive to plant than the hybrid B# currently sown. This is true for Farms 2, 5, 6, 14 and 15. A Positive difference, in this column indicate the opposite outcome. The farms where hybrid A1 is less expensive to plant than the B# hybrids are 3, 4, 7, 8, 9, 10, 11, 16, 19 and 20. Farms 1, 12, 13, 17 and 18 do not have a change in planting costs since these farms do not switch hybrids. Dollar values are measured on a per acre basis, $/ac. Farms 5 and 15, hybrids B4 and B9, have lower planting costs than A1 due to fewer seeds planted per acre despite the seed being more expensive per 1,000 seeds.

Farms 2, 6 and 14, which planted hybrids B2 and B5, are less costly compared to planting the A1 hybrid, which is due to reduced seeding rate and lower seed costs per-1,000 seeds. The increase in costs, or loss, created by switching to A1 for these five farms ranged from a low of $2.61/acre (Farm 15 hybrid B9), to a high of $25.56/acre (Farm 14 hybrid B3). The remaining ten farms — 3, 4, 7, 8, 9, 10, 11, 16, 19, and 20 — experienced a drop in planting expense or cost savings by switching from their original B# hybrids to A1 seeds. The savings ranged from a little as $1.31/acre (Farm 4 hybrid B3), to as much as $32.28/acre (Farm 20 hybrid B11). While these are real savings or losses, they do not measure the complete change in profitability. To answer that question requires them to be combined with information about their effects on yields translated into changes in revenue.

Table 1. List of varying actual and predicted seeding costs, planted populations and the resulting savings or loss due to hybrid selection and change for UNL TAPS hybrid corn seed varieties planted in the spring of 2018, by farm and hybrid identification number

| Farm | Hybrid |

Actual |

Actual |

Predicted |

Expected |

Savings/Loss |

| Number | Number |

Costs |

Planted |

Costs |

Planted |

By Switching |

|

$/Acre |

Seeds/Acre |

$/Acre |

Seeds/Acre |

Hybrid $/Acre | ||

|

1 |

A1 |

$94.95 |

33,000 |

$94.95 |

33,000 |

$0.00 |

|

2 |

B1 |

$74.43 |

26,000 |

$96.96 |

33,700 |

($22.53) |

|

3 |

B2 |

$107.11 |

34,000 |

$96.96 |

33,700 |

$10.15 |

|

4 |

B3 |

$98.27 |

33,000 |

$96.96 |

33,700 |

$1.31 |

|

5 |

B4 |

$94.25 |

28,000 |

$96.96 |

33,700 |

($2.71) |

|

6 |

B5 |

$77.35 |

32,500 |

$96.96 |

33,700 |

($19.61) |

|

7 |

B6 |

$120.05 |

34,000 |

$96.96 |

33,700 |

$23.09 |

|

8 |

B2 |

$103.96 |

33,000 |

$96.96 |

33,700 |

$7.00 |

|

9 |

B4 |

$100.98 |

30,000 |

$96.96 |

33,700 |

$4.02 |

|

10 |

B7 |

$99.66 |

33,500 |

$96.96 |

33,700 |

$2.70 |

|

11 |

B8 |

$103.20 |

32,000 |

$96.96 |

33,700 |

$6.24 |

|

12 |

A1 |

$97.82 |

34,000 |

$97.82 |

34,000 |

$0.00 |

|

13 |

A1 |

$97.82 |

34,000 |

$97.82 |

34,000 |

$0.00 |

|

14 |

B5 |

$71.40 |

30,000 |

$96.96 |

33,700 |

($25.56) |

|

15 |

B9 |

$94.35 |

34,000 |

$96.96 |

33,700 |

($2.61) |

|

16 |

B10 |

$99.20 |

32,000 |

$96.96 |

33,700 |

$2.24 |

|

17 |

A1 |

$96.38 |

33,500 |

$96.38 |

33,500 |

$0.00 |

|

18 |

A1 |

$97.82 |

34,000 |

$97.82 |

34,000 |

$0.00 |

|

19 |

B2 |

$107.11 |

34,000 |

$96.96 |

33,700 |

$10.15 |

|

20 |

B11 |

$129.24 |

31,000 |

$96.96 |

33,700 |

$32.28 |

Revenue Changes

The profit equation has two primary factors: costs and revenues. Additional costs and reduced revenues negatively alter profit, while costs savings and increased revenues have a positive effect on profit. The question asked here is related to a change in profit, measured as the difference in revenue and costs between planting B# hybrids versus the A1 hybrid. This method of determining the change in profit is an application of the partial budgeting technique.

Changes in revenue require knowing two facts. First, the value of corn bushels. Second, the change in productivity measured in number of bushels, particularly B# hybrid yield versus those simulated for hybrid A1. Once these yields are known, it is a simple task to calculate revenue changes. These differences in yields are multiplied by their market value, establishing a change in revenue value for each farm. These revenue differences are then combined with the cost differences to provide estimates of profitability changes.

There are three possible outcomes each switch in corn hybrid; 1) profit will increase, 2) profit will decrease, or 3) profit will remain constant. The key to an accurate analysis is using as accurate information as possible. This includes yield differences, costs, and commodity values. Fortunately, the TAPS venue provides the perfect data to make comparisons. While the different hybrids do not physically occupy the same space at the same time, they are adjacent plots with similar soil, weather, and temperatures. Due to the careful planning and scientific precision with which the TAPS contest is run, the information and data have a high degree of accuracy and integrity.

The TAPS hybrids A1 and B#s are planted and grown side by side simultaneously under identical conditions in the same field during the same season. The only difference among the farms, aside from seeding rate and hybrid, are applied nitrogen fertilizer (N) and irrigation levels. Hybrid A1 farms are located next to and around the different Hybrid B# farms in the same field. The data collected is reported for the TAPS 2018 irrigated corn contest in North Platte, Nebraska. The information is used to build a statistical model that accounts for variations in irrigation and N applications, which are managed uniquely by farm #. The statistical model of yields is developed using ordinary least squares (OLS) regression for farms that planted and grew the A1 hybrid. This model is the tool used to “biologically simulate productivity”. This OLS regression best fit model has an R square value, linearly explaining 96.3% of the variation in the data, (by any measure a pretty good fit).

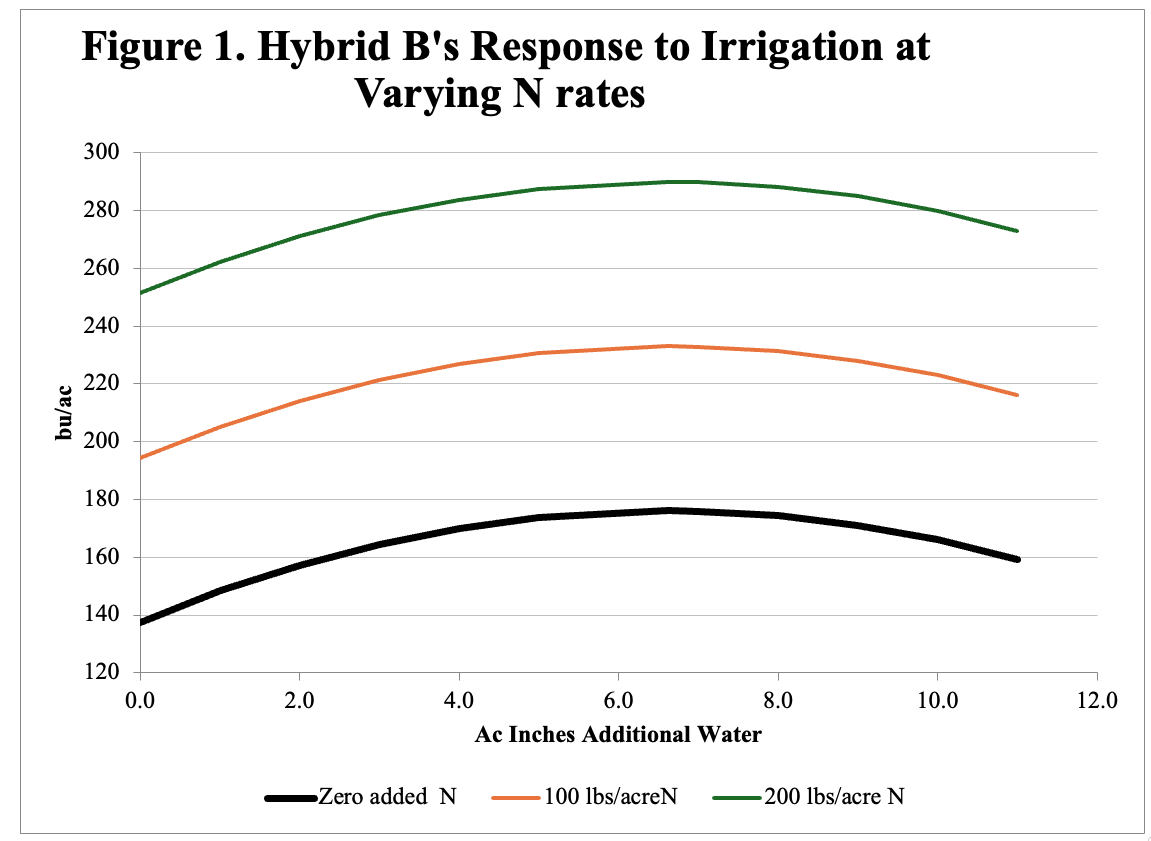

The explanatory variables include irrigation quantity (in acre inches and acre inches squared) and pounds of nitrogen (N) fertilizer applied per acre. This model is visually depicted by the three curves drawn in Figure 1 using three different levels of added N, 0, 100 and 200 lbs/ac. The horizontal axis shows varying amounts of added irrigation water in one acre inch increments. The estimated base yield (yield without any added water or N fertilizer) can be seen in Figure 1 as the dark black line. This line intersects with zero added water (Y-axis). The base yield prediction according to the model was 137.62 bu/ac. This base yield is representative of the yield for the control, Farm 12, which produced an average yield of 137.6 bu/acre.

The three curves in Figure 1 are illustrative of the forecasted yield per acre (Y-axis) at three distinct levels of applied N, 0, 100 and 200 lbs/acre. The yields for each N level increase as added irrigation increases (X-axis). Each added acre inch of irrigation was estimated to increase corn grain yields by 11.6 bu/acre while simultaneously that additional acre inch squared penalized grain yields by a -.877 bu/acre. The squared variable has a dampening effect (diminishing return) and limits the effectiveness of irrigation water to increase yield by creating a ceiling or maximum yield available. This is illustrated well in Figure 1, where yields from irrigating reach a maximum at approximately 6.6 acre inches and then decline with increasing amounts of water.

Not to be redundant, but it is helpful to remember that these three lines represent three levels of added N for the corn hybrid A1, covering the 2018 crop year planted in North Platte at the West Central Research, Extension and Education Center (WCREEC) TAPS contest area. Each added pound of N was estimated to have increased corn grain production by about .57 bu/acre. It is important to remember that these yield predictions/forecasts of the model are limited to and are only valid within the range of N applications and irrigation (added water) observed during that year for that location. One could hardly expect the model to accurately forecast yield if 400 lbs of N/acre, or 20 acre inches of water were used, for that matter a different year or site, since these factors are not included in the models development.

The model is operationalized for each farm by substituting in their irrigation and N fertilizer amounts applied by each contestant for their particular farm. The resulting forecasted yields are the best estimates of what would happen had hybrid A1 been planted instead of the B# hybrid they opted to grow. The forecasted yields are then used to compare with the observed yields to derive the change in yields by farm.

The predicted, observed, and yield differences for each of the B# hybrids are listed in Table 2 as well as the predicted yields for the five farms that planted hybrid A1. To be clear, each prediction is based on the actual amounts of applied N and added irrigation water for the respective farm. This method makes it simple and straightforward when making yield comparisons among hybrid seed varieties.

Table 2. The difference in the observed yields (hybrid B yields) minus the expected yields (hybrid A1 yields) equal the yield difference; listed by farm number and hybrid for all TAPS corn farms. Positive values for the yield difference indicate an expected yield loss due to switching hybrids, negative values indicate a yield gain due to switching hybrids. The yield difference is a measure of how accurate the model predictions are in the instance of farms 1, 12, 13, 17 and 18. These farms were not switched.

|

Actual |

Expected |

Hybrid |

Yield |

|||

|

(Hybrid B) |

(Hybrid A) |

Corn Seed |

Difference |

|||

|

Farm # |

Yields |

Yields |

Hybrid |

Bu/Acre |

||

|

1 |

274.6 |

272.2 |

A1 |

2.4 |

||

|

2 |

255.3 |

288.3 |

B1 |

33.00 |

||

|

3 |

262.0 |

278.6 |

B2 |

16.60 |

||

|

4 |

248.6 |

297.5 |

B3 |

48.90 |

||

|

5 |

246.6 |

273.7 |

B4 |

27.10 |

||

|

6 |

233.6 |

267.8 |

B5 |

34.20 |

||

|

7 |

288.3 |

282.2 |

B6 |

-6.10 |

||

|

8 |

240.3 |

292.3 |

B2 |

52.00 |

||

|

9 |

270.0 |

304.1 |

B4 |

34.10 |

||

|

10 |

273.6 |

285.0 |

B7 |

11.40 |

||

|

11 |

257.3 |

278.5 |

B8 |

21.20 |

||

|

12 |

137.6 |

137.6 |

A1 |

0.047 |

||

|

13 |

257.6 |

255.5 |

A1 |

2.1 |

||

|

14 |

260.6 |

280.4 |

B5 |

19.80 |

||

|

15 |

279.0 |

283.7 |

B9 |

4.70 |

||

|

16 |

240.0 |

258.9 |

B10 |

18.90 |

||

|

17 |

222.3 |

222.8 |

A1 |

-0.5 |

||

|

18 |

264.3 |

267.6 |

A1 |

-3.3 |

||

|

19 |

256.6 |

281.7 |

B2 |

25.10 |

||

|

20 |

272.0 |

288.3 |

B11 |

16.30 |

||

The forecasts of hybrid A1 yields for farms that had originally raised this hybrid — Farms 1, 12, 13, 17, and 18 — reflect how well the model predicts within sample observations. The difference of the two values is commonly referred to as the prediction or forecast error. These forecast errors are relatively small; the largest error in absolute terms is 3.3 bu/ac less than the actual yield for farm 18. The other prediction errors are 2.4 (Farm 1), 0.047 (Farm 12), 2.1 (Farm 13), and finally 0.5 (Farm 17).

Of all the forecast for the B# hybrids only B6 (Farm 7) exceeded its sA1 simulated yield. The predicted yield difference for this farm was -6.1 bu/ac less for the A1 hybrid. The next closest yield among B# hybrids is Farm 15 (hybrid B9), where hybrid A1 is predicted to be 4.8 bu/ac more. Farm 8 (hybrid B2) was predicted to benefit the most from switching to hybrid A1 with a 52.0 bu/acre gain in yield. Eight of the 15 B# hybrid farms were forecast to have more than a 20 bu/acre increase in yield when they switched to hybrid A1. These included Farms 2, 4, 5, 6, 8, 9, 11, and 19. Farms 3, 14, 16, and 20 have A1 yields from 10 to 20 bu/ac more than the B# hybrids with Farm 15 A1 yields nearly 5 bu/ac more than B9.

The yield changes for each farm were multiplied by the contest-ending bushel value of $3.20/bu. This calculation establishes a revenue for each predicted yield change. These revenues, along with the respective changes in costs per acre due to hybrid switching are combined to estimate the change in profit per acre. These profits are listed as the last column of Table 3. In all cases for Farms where B# hybrids were replaced by A1 hybrids, profitability increased, either through cost savings, a revenue increase, or a combination of the two.

As indicated earlier Farm 7 (hybrid B6) was the only farm with a higher yield before the switch, with 288.5 bu/acre yields versus the A1 hybrid with a forecasted 282.2 bu/acre. This decrease in yield resulted in a negative revenue change of -$19.52/ac, combining this with the seed cost savings of $23.09/ac, making the switch to A1 from B6 increases profit by $3.57/acre. If hybrid B6 on Farm 7 had produced an additional 1.12 bu/ac grain, or if corn were valued at $0.59/bu higher ($3.79/bu), hybrid B6 would be as profitable as change to hybrid A1.

These outcomes suggest a basic framework whereby seed selection could be considered. Seed selection should be based on value, not simply on costs or productivity alone. This idea is based on maximizing profits, not maximizing production nor minimizing costs. The next closest farm in profitability to Farm 7 is Farm 15. If Farm 15 switched to hybrid A1, it would have an estimated planting cost increase of $2.61/acre with an offsetting revenue gain of $15.34 making the switch to the A1 hybrid $12.73/ac more profitable.

This reinforces the importance of making the choice of hybrid selection based on value, not cost or productivity — but rather their combination. This becomes even more potent when bundled with good grain marketing practices. Farms 2, 6, and 14, using hybrids B1 and B5, had lower seed costs than hybrid A1 by at least $19/acre. Even with this relatively large seed cost savings, these three farms didn’t achieve higher profits because the loss of productivity of 33.0, 34.2 and 19.8 bu/ac outweighed the cost saving of buying the cheaper seed. This reduced productivity resulted in a revenue difference of $105.60/acre for Farm 2, $109.22/acre for Farm 6, and $63.22/acre for farm 14.

The total effect of the switch to hybrid A1 resulted in increased profits of $83.11/acre, $89.61/acre and $37.66/acre for each farm respectively. Three of the fifteen farms gained more than $113/acre by switching to the A1 hybrid, Farms 4, 8, and 9. Their increase in profit is $157.57, $173.58, and $113.17 respectively. Thirteen of the fifteen B# hybrid farms were forecast to increase profits by at least $37.66/acre.

Table 3. Summary of costs savings/losses, increased/decreased revenues and profit changes for all switched hybrid B’s, farm 1, 12, 13, 17, and 18 were not switched and were omitted from the table

| Farm | Hybrid | Costs Savings/Loss | Revenue Change | Profit Change |

| Number | Identification | From Hybrid | From Production | From Hybrid |

| Number (HIN) | Switch $/Acre | Difference $/Acre | Switch $/Acre | |

|

2 |

B1 |

($22.53) |

$105.60 |

$83.07 |

|

3 |

B2 |

$10.15 |

$53.12 |

$63.27 |

|

4 |

B3 |

$1.31 |

$156.48 |

$157.79 |

|

5 |

B4 |

($2.71) |

$86.72 |

$84.01 |

|

6 |

B5 |

($19.61) |

$109.44 |

$89.83 |

|

7 |

B6 |

$23.09 |

-$19.52 |

$3.57 |

|

8 |

B2 |

$7.00 |

$166.40 |

$173.40 |

|

9 |

B4 |

$4.02 |

$109.12 |

$113.14 |

|

10 |

B7 |

$2.70 |

$36.48 |

$39.18 |

|

11 |

B8 |

$6.24 |

$67.84 |

$74.08 |

|

14 |

B5 |

($25.56) |

$63.36 |

$37.80 |

|

15 |

B9 |

($2.61) |

$15.04 |

$12.43 |

|

16 |

B10 |

$2.24 |

$60.48 |

$62.72 |

|

19 |

B2 |

$10.15 |

$80.32 |

$90.47 |

|

20 |

B11 |

$32.28 |

$52.16 |

$84.44 |

Discussion

The TAPS contest and accompanying information from it provides a unique opportunity to scientifically investigate many different management questions and their impact on profitability. Like many decisions in agricultural production, understanding and comparing cost and benefit, as well as determining value, is more important than price or productivity alone. Shooting for maximum profit is generally a superior choice than focusing on maximum yields.

Certainly, selecting the “best hybrid” of corn to grow in any one field is a complex issue, since every farm and field is different. This uniqueness and difficulty not only include the physical attributes of the farm but encompasses the management practices, abilities and understanding of its operator. No one can make the best choice in a vacuum. Information, knowledge, and experience are all important. It should be expected that even the right or best choice doesn’t always guarantee a favorable or desired outcome.

From this work, it is evident that knowledge about expected seed productivity among hybrids, the cost difference of those hybrids, and the expected value of the production are invaluable components needed to make that best and/or most profitable choice. When you consider the potential impact that this decision has on the annual per acre net returns, it is almost mind boggling. Using the profit differences generated from this work it becomes evident that this choice is important to sustainability.

For example. a 1,000-acre planting decision, with an OK seed choice according to calculations made here, could mean as little as a $3,570 reduction in profit (Farm #7, B6 hybrid planted instead of A1). But with a poor choice (intentional or not) Planting Farm 8, planting hybrid B2 resulting in a reduction in return of $173,580. It becomes apparent quite quickly why the right seed hybrid, management and cost control are critical to maintaining an economically successful operation.

The Tip from TAPS to take home is that it may be worth some extra time and effort to do some figuring and exploring to find the best seed value you can. Remember, just because a seed is expensive doesn’t make it the right or wrong choice. As illustrated, expensive seed may be justified given the right yield potential and market conditions. The same could be said of inexpensive seed. The opposite is also true.

What has not been considered here is the effect of varying technology among seeds. This factor is not difficult to add into the decision process. By including the reduction or increase in costs for each type of seed, it can be incorporated into the analysis of seed value. To illustrate, a Roundup Ready corn seed is valued at $20/acre more than a conventional hybrid by the seed dealer. The expected yields are the same, but the added cost of using the conventional seed compared to the Roundup Ready is $30/acre due to the use of alternative weed treatments needed. If the cost of planting the Roundup Ready is $92/acre, the conventional seed cost $72/acre purchase cost, plus the added weed control cost of $30/acre, making its actual or realized cost $102/acre. That is $10/acre more expensive than the Roundup Ready, with no expected increase in revenue.

There are so many places to use this type of value comparison. Selecting a hybrid is just one. The important thing to remember is that even small choices can often make a difference. The hope is that this type of marginal analysis can be an aid in making the better choices. In today’s farming environment, it takes many good choices to succeed, and far fewer bad ones to fail. The most economically successful farms in TAPS have, to date, been those farms that have a balanced approach in all facets of their operation, including business, management and production.